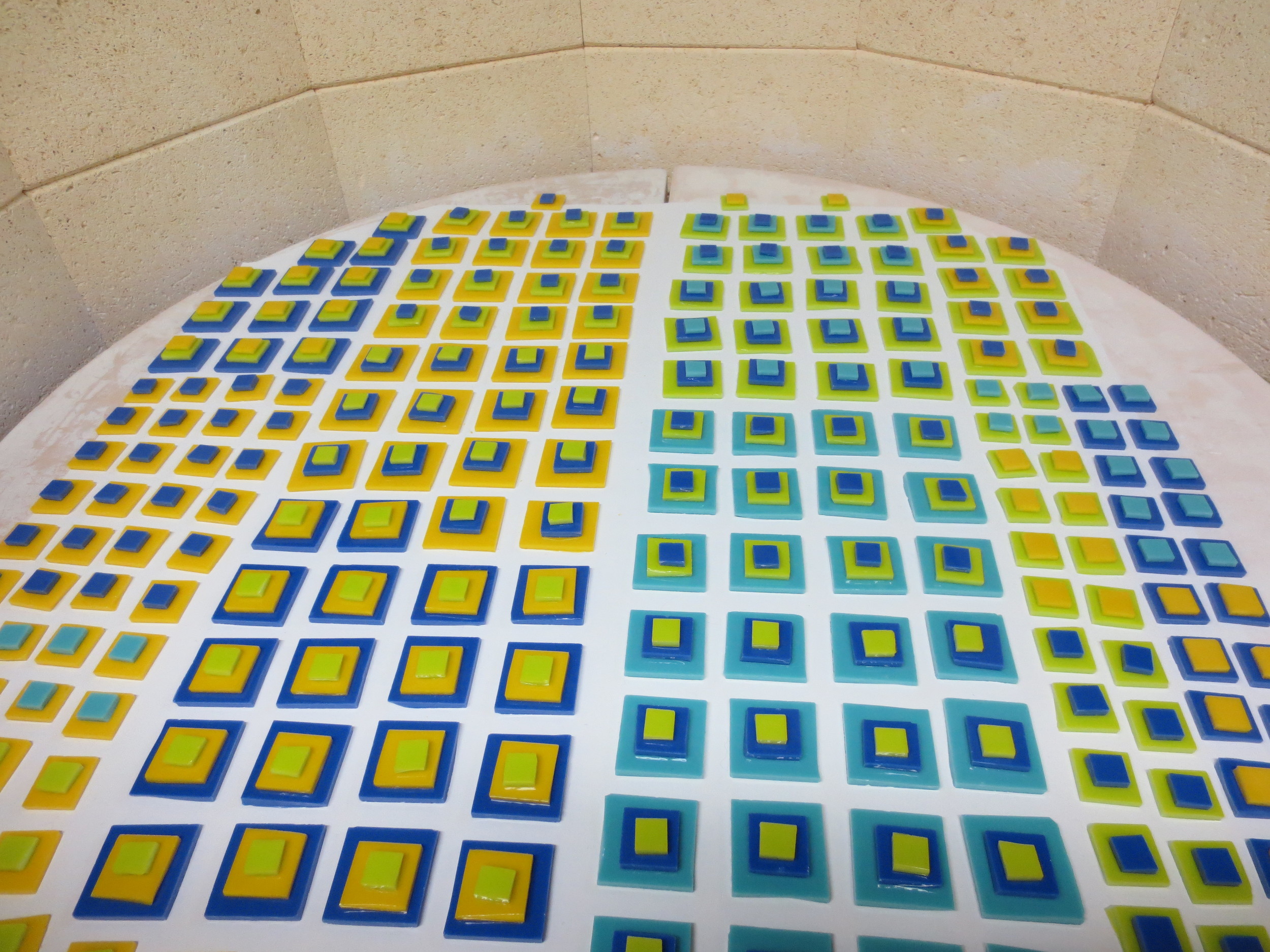

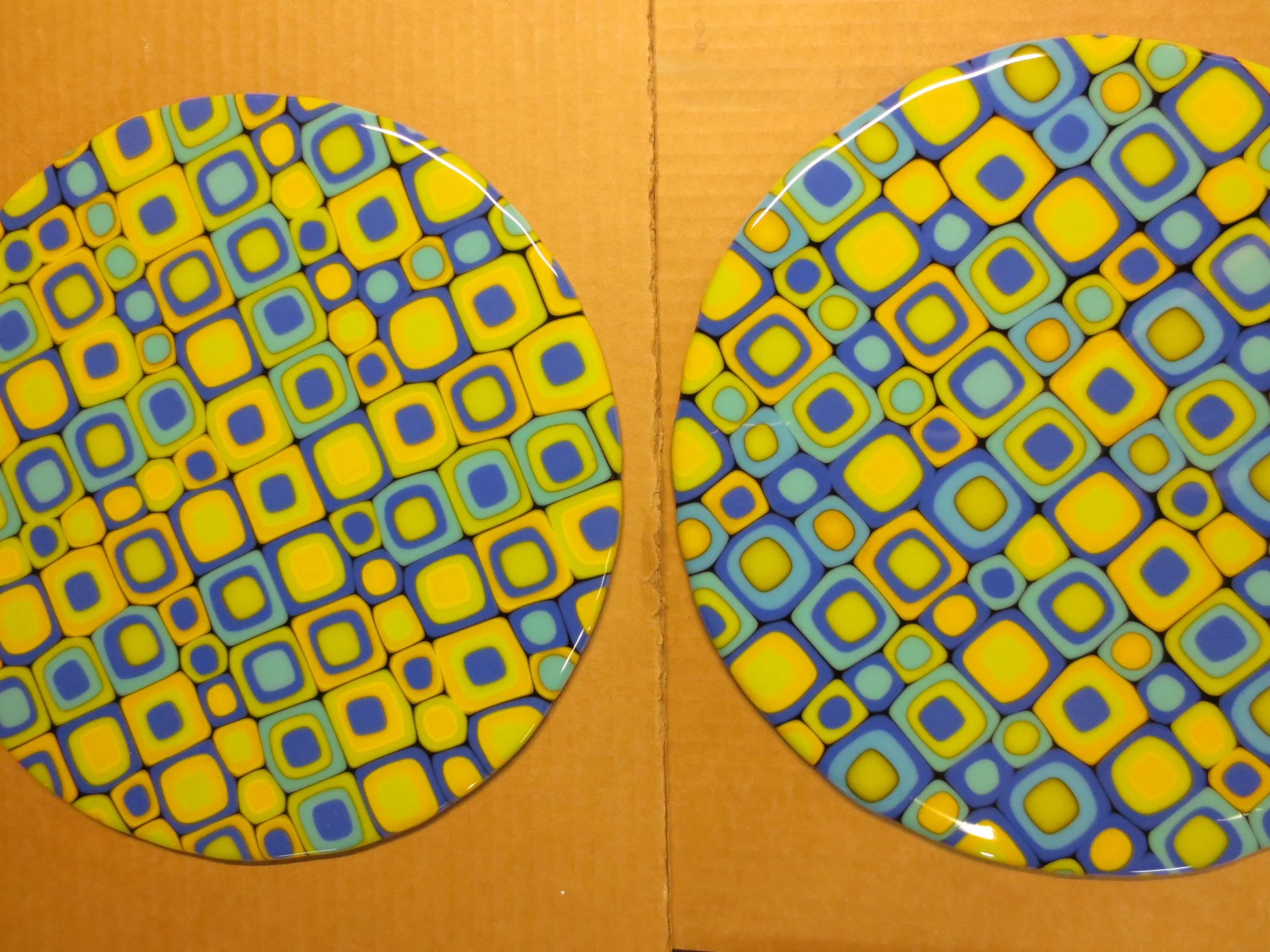

Color swatch

Before selecting a new color scheme, a test tile is fused. One is never certain of color compatibility until the you can see how they look when melted together.

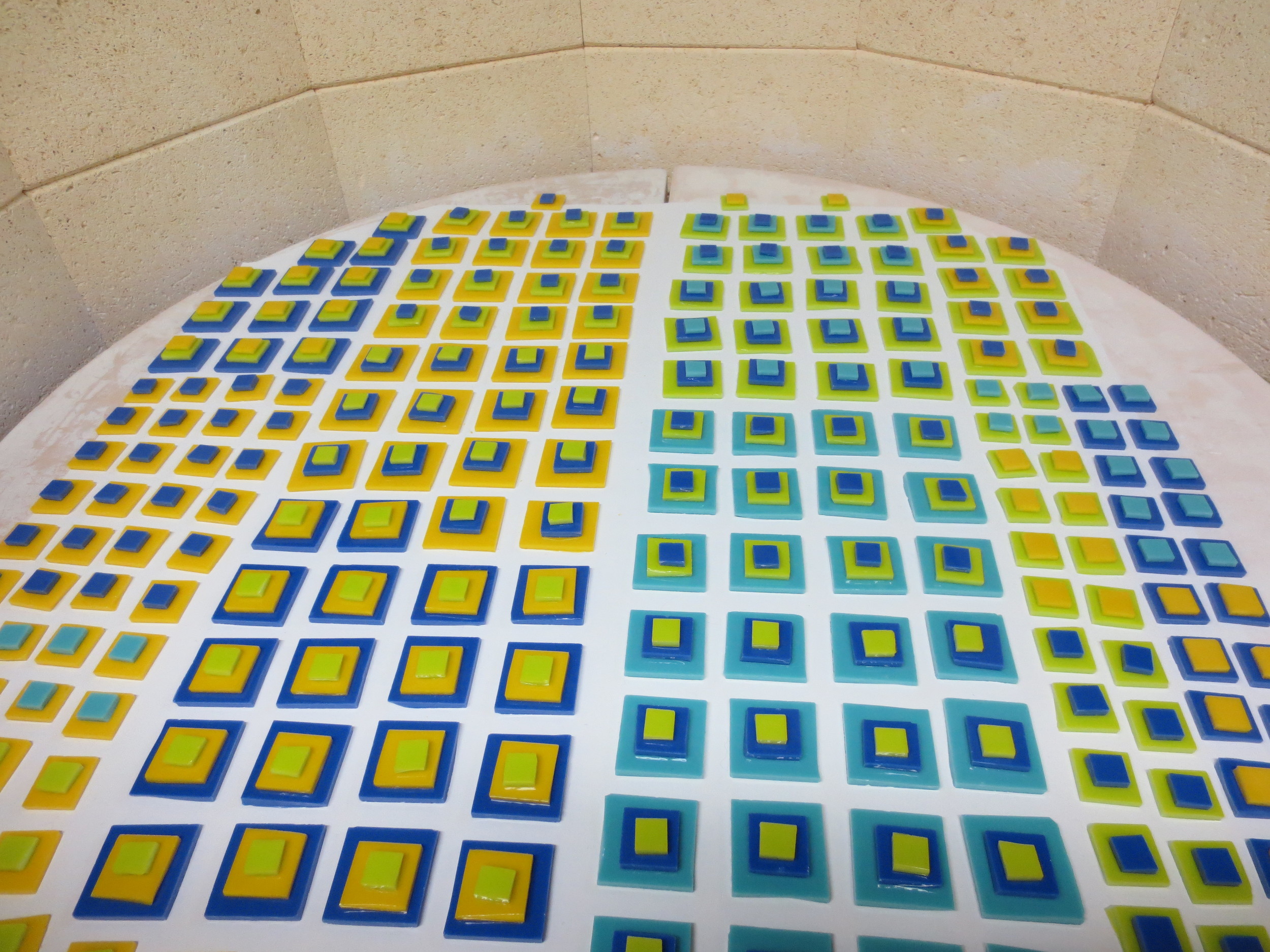

Set up tiles

Squares are cut from a 12"x12" sheet of glass and laid out two and three deep on the kiln shelf.

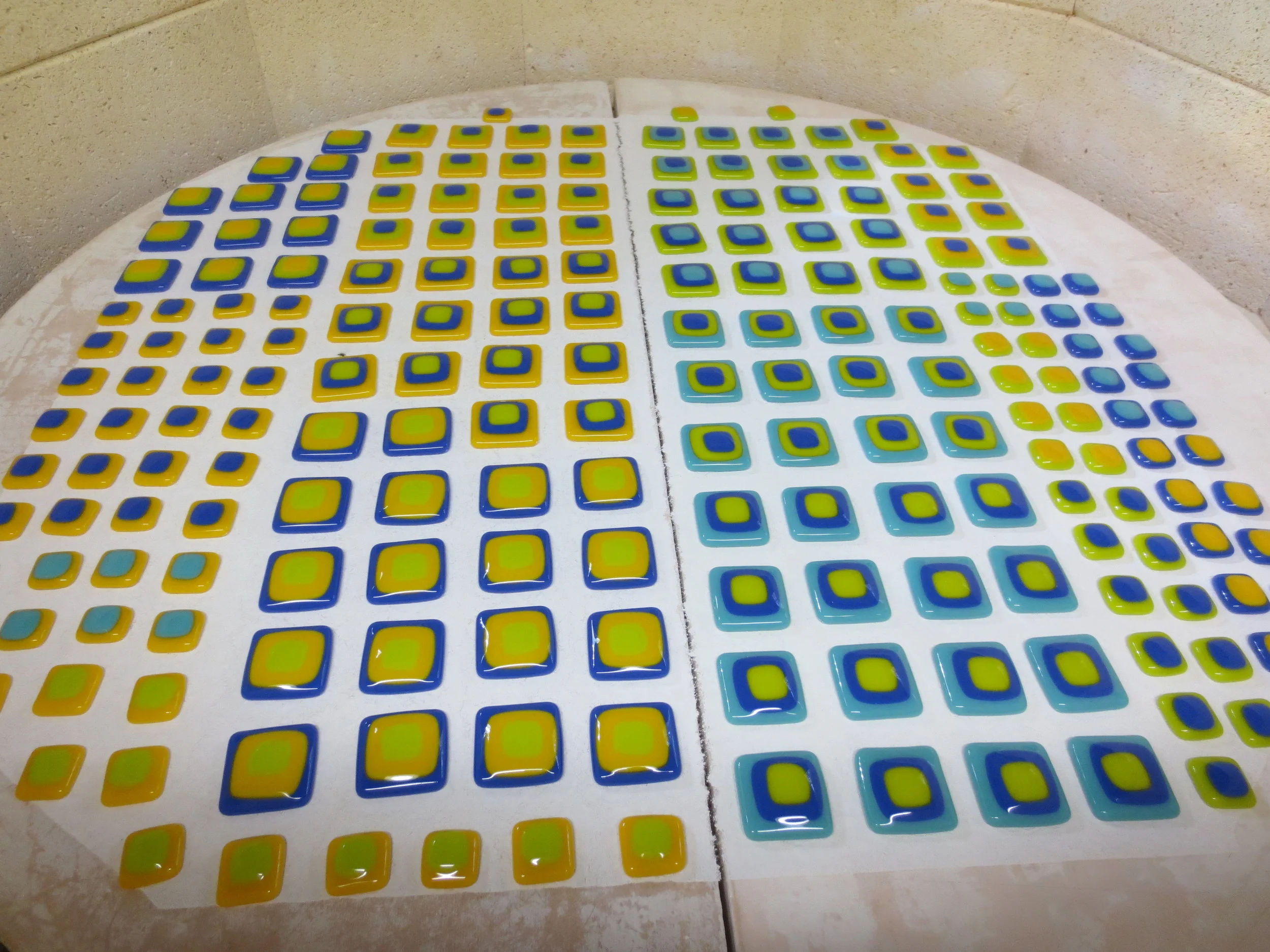

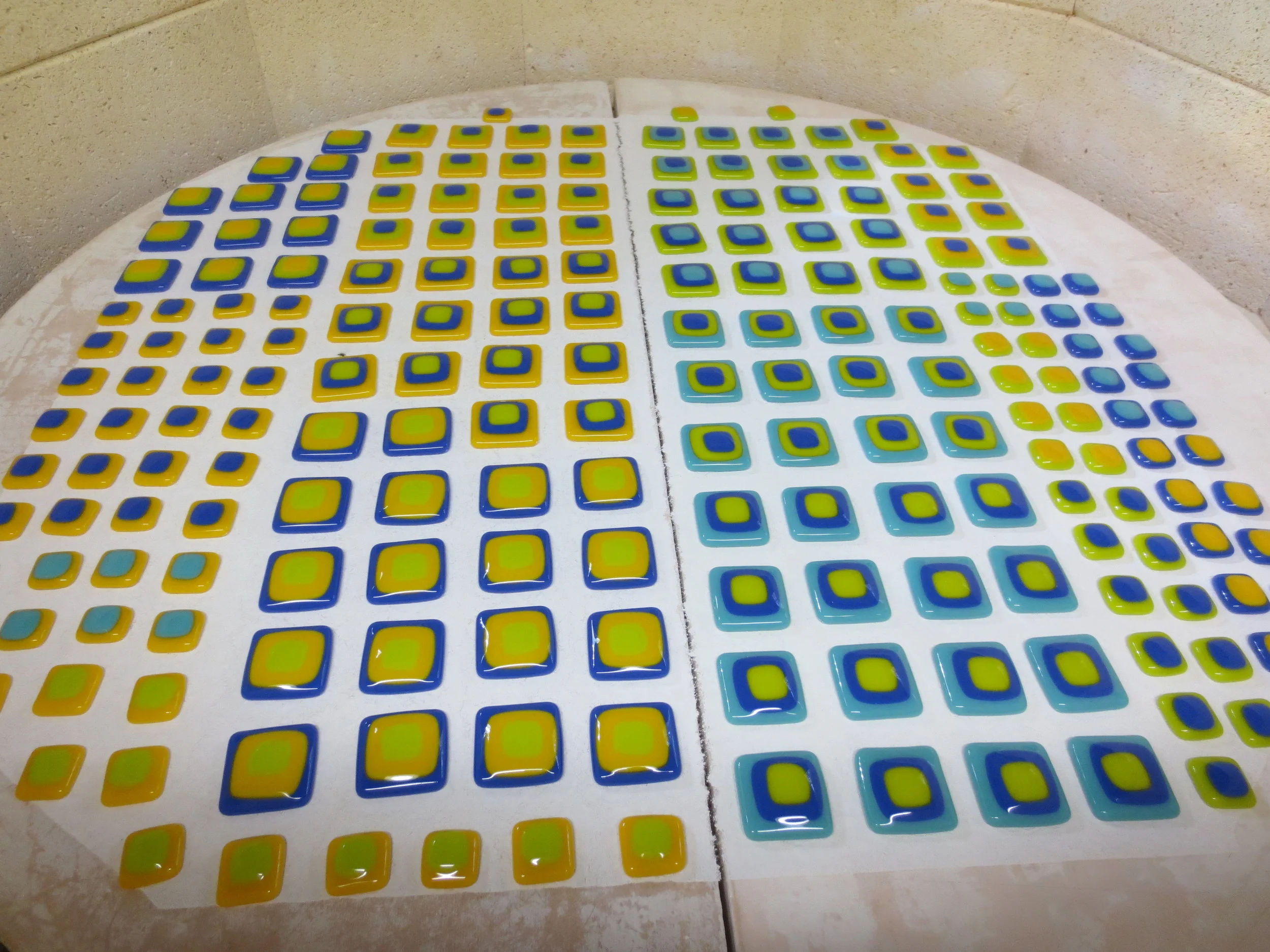

Fused tiles

After an overnight kiln cycle at temperatures reaching 1125 degrees F, the tiles are ready to clean and sort.

sorted tiles

Color combinations are sorted and ready to start designing the pattern.

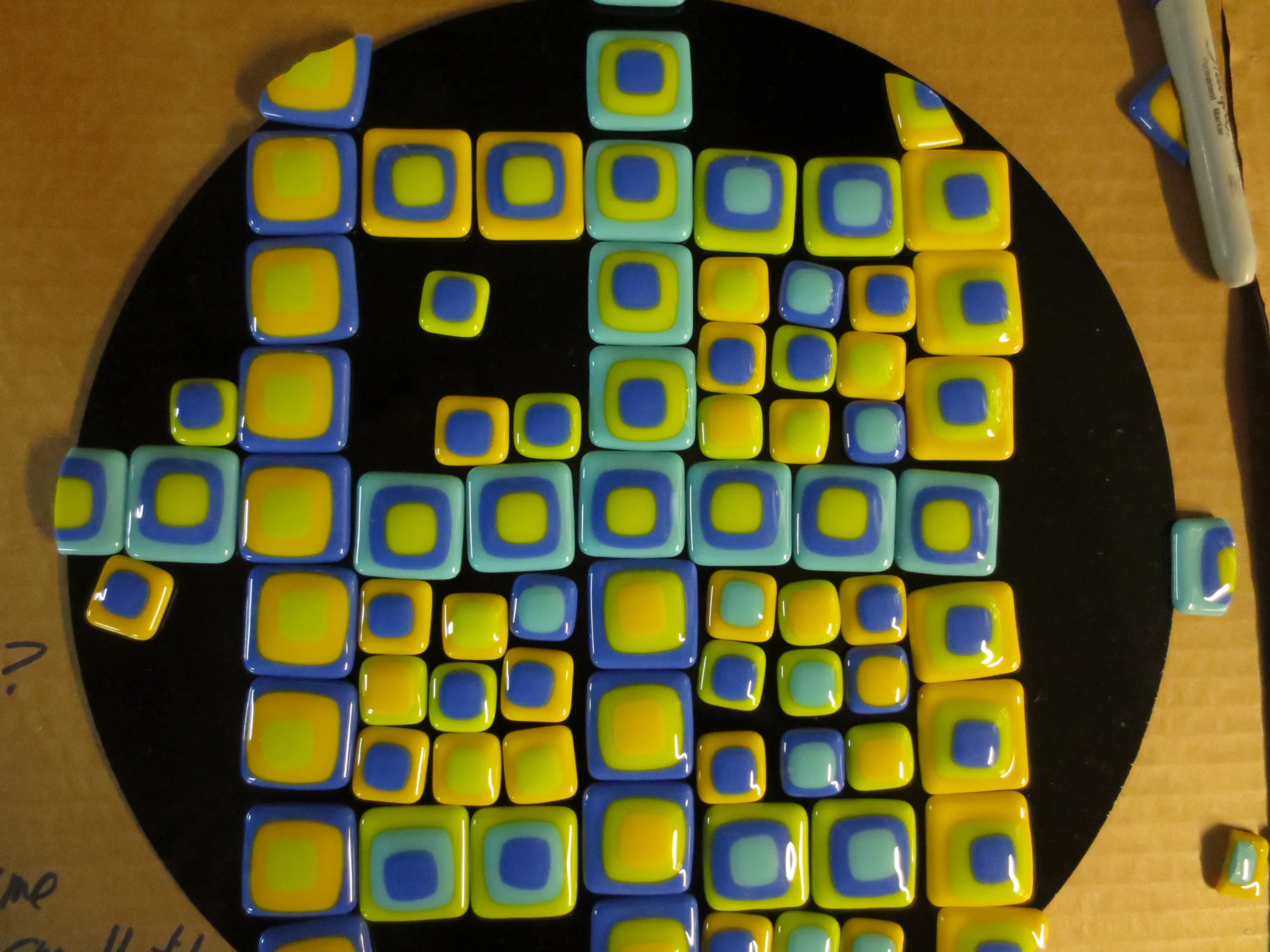

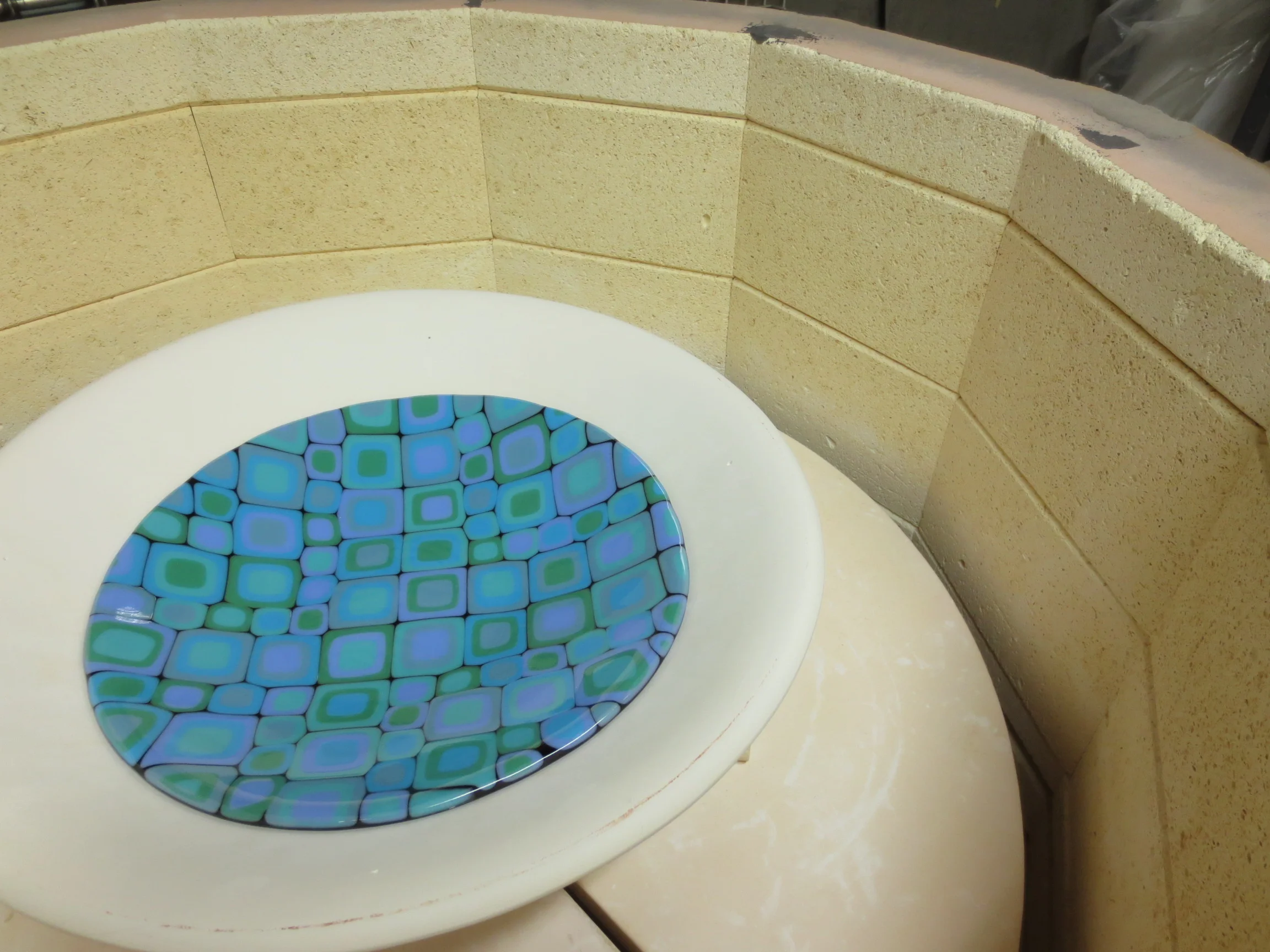

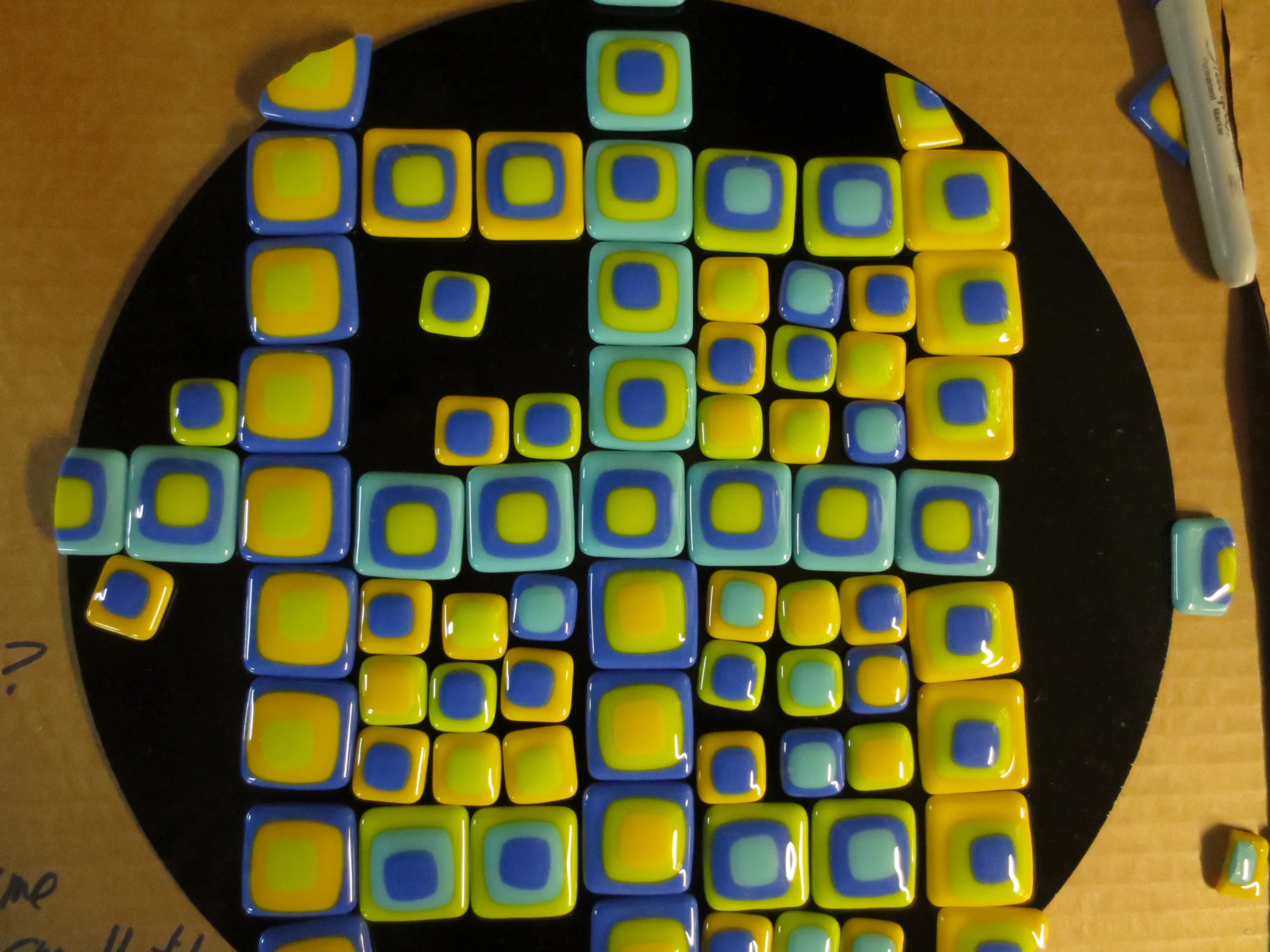

pattern design

Tiles are arranged in a pattern on an opaque circle of black glass (base). This pattern did not survive the design process (I started over!)

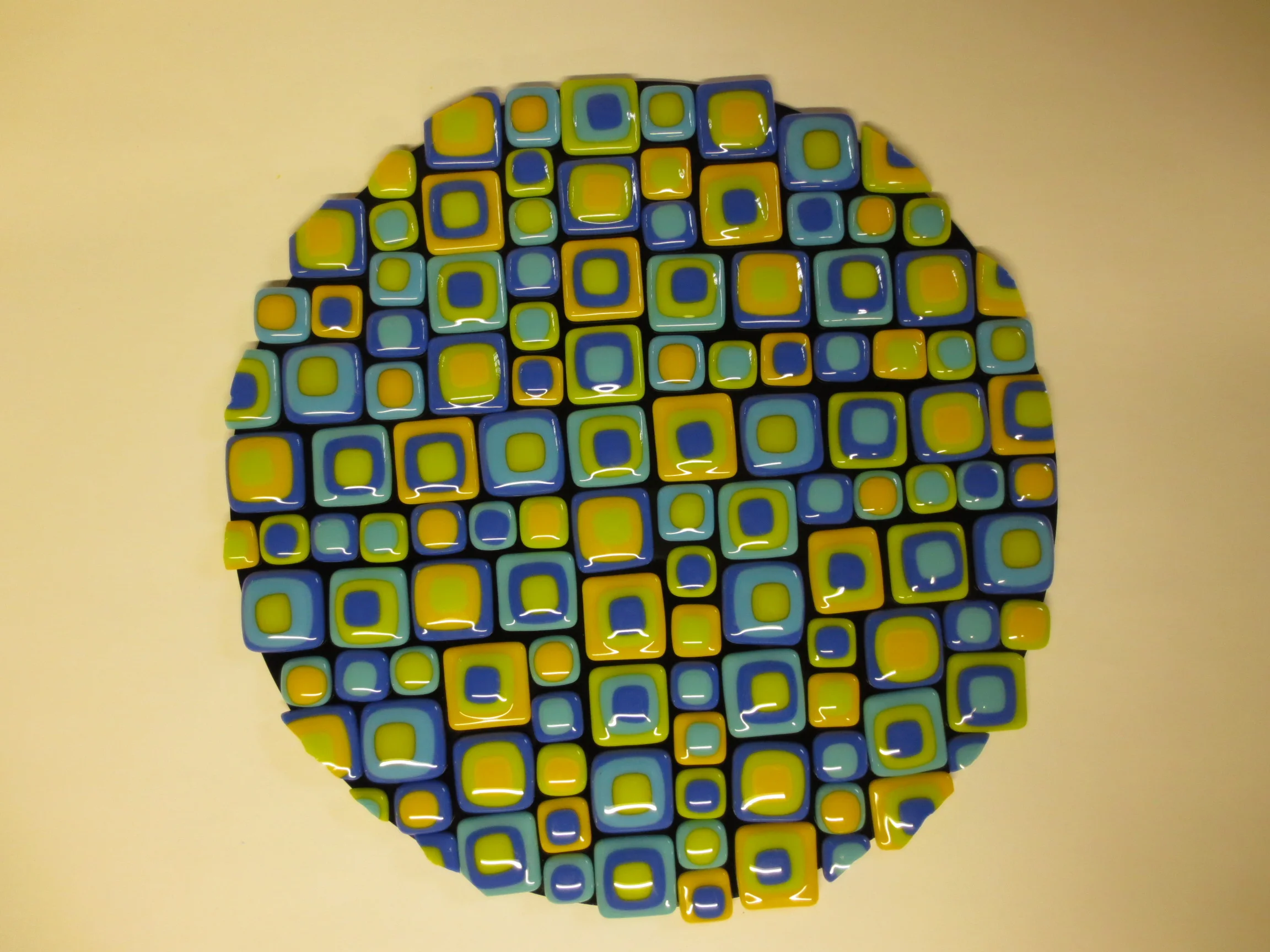

ready to fire!

Once the pattern is determined, the entire base is filled with tiles and ready to fire. During this cycle, the tiles will fuse completely to the black circle, creating a bowl blank.

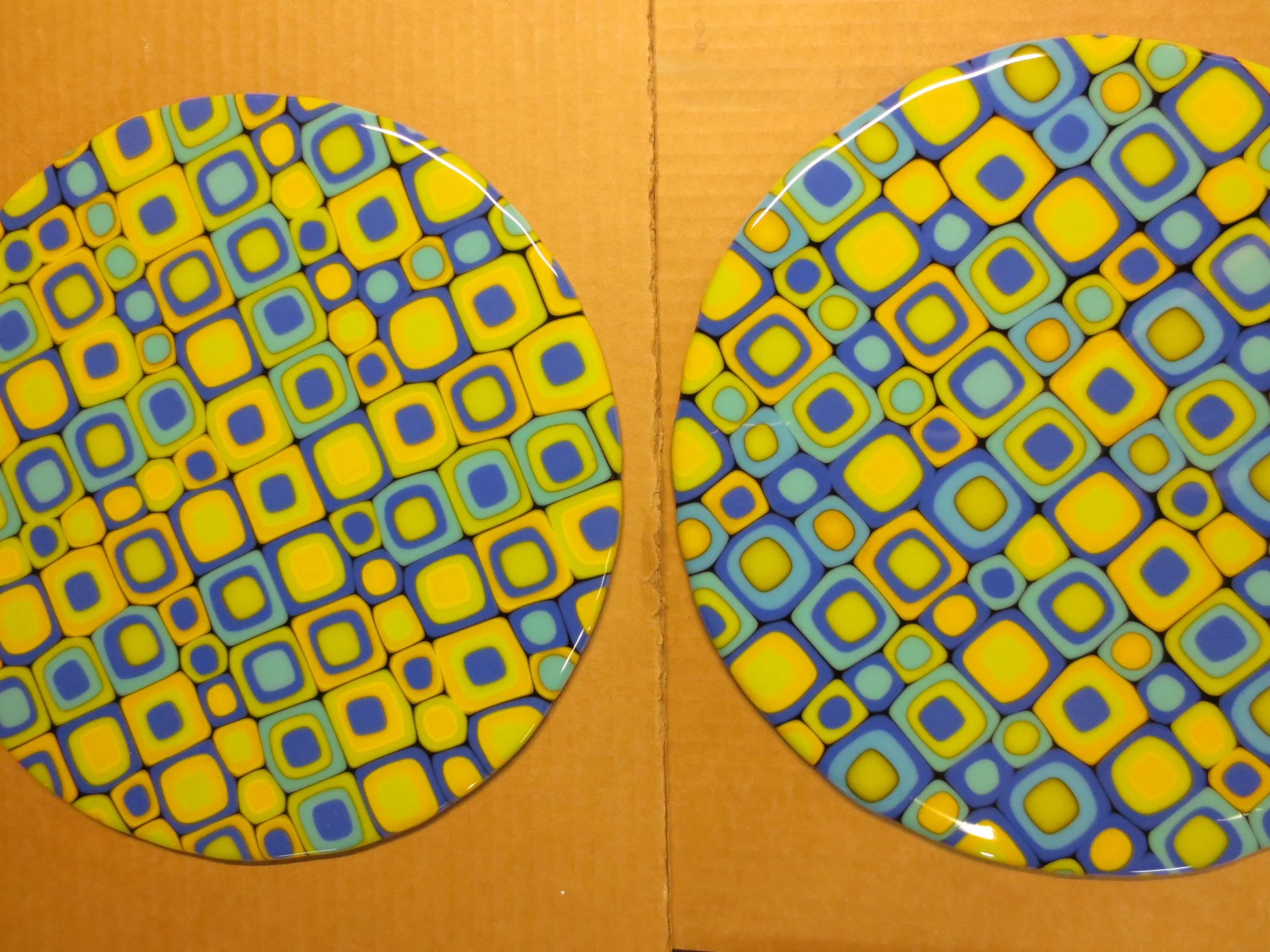

finish fire

After machine and hand grinding to shape, the blanks are signed and coated with an overspray to prevent devitrification and then finish fired. Once removed from the overnight cycle, the bowl blanks are ready to slump (at a lower temperature) into a porcelain bowl mold.

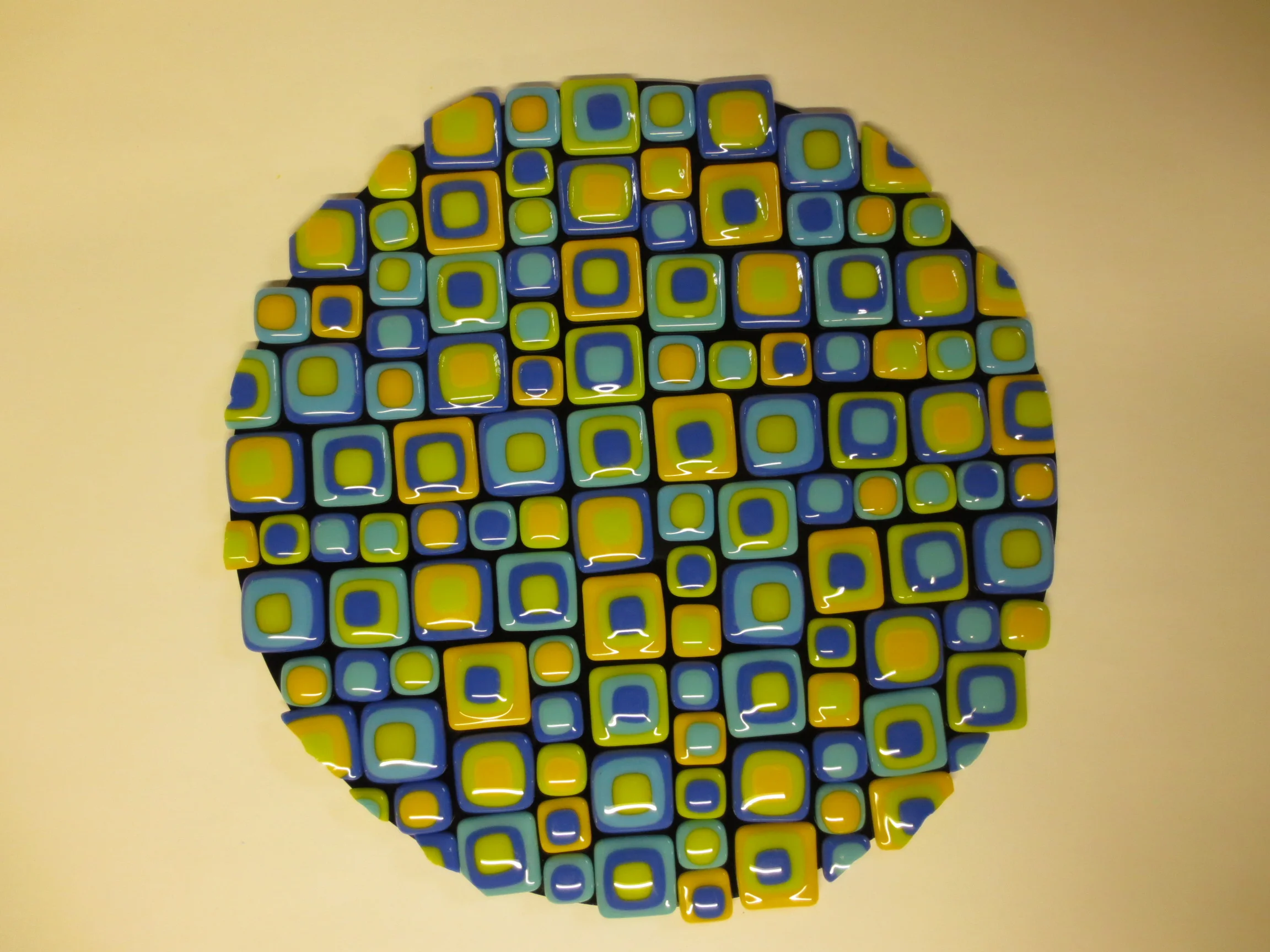

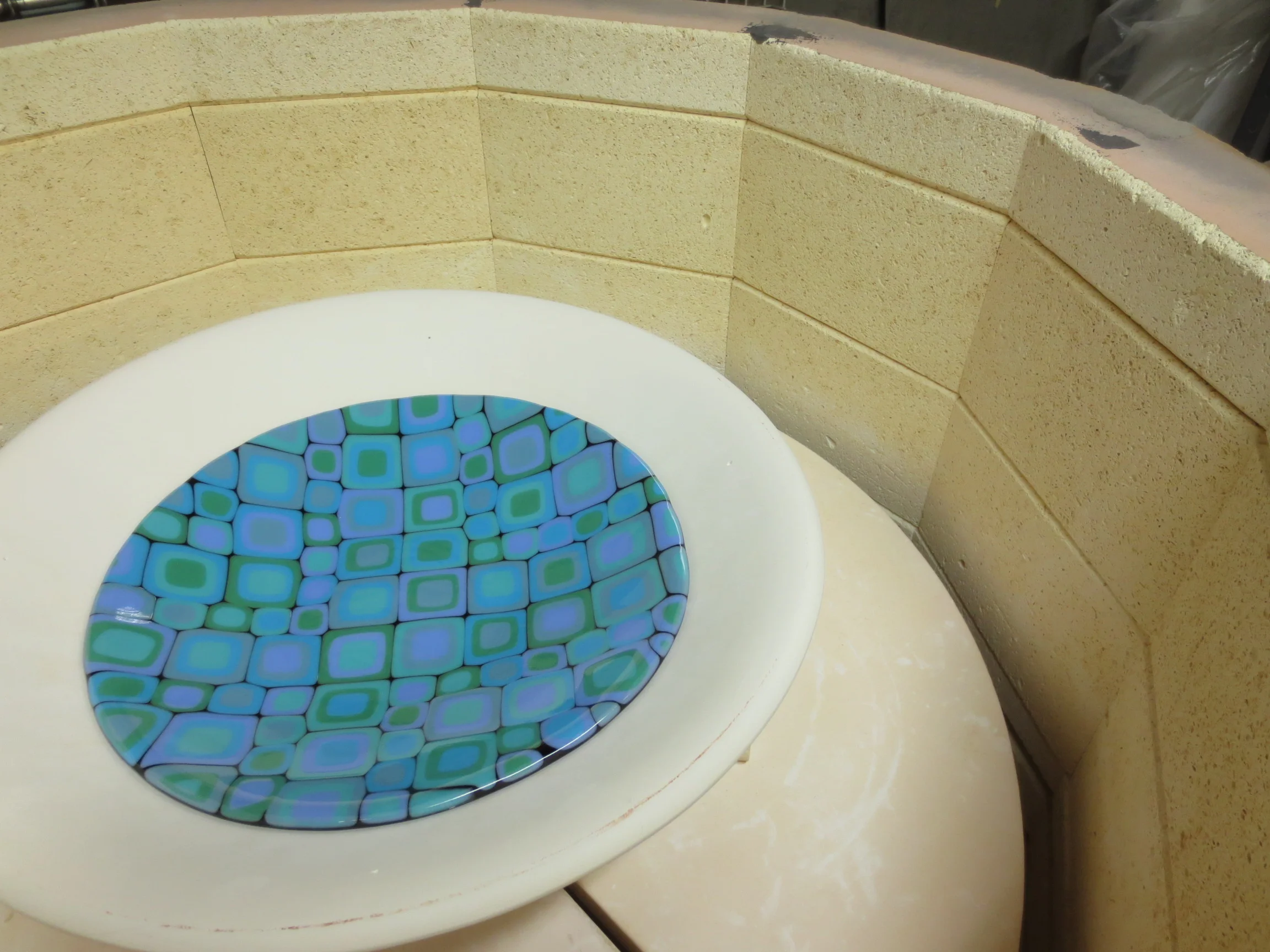

completed bowl

In the morning, the kiln is opened to reveal a slumped bowl with a brushed matte black bottom and a colorful and glossy top.